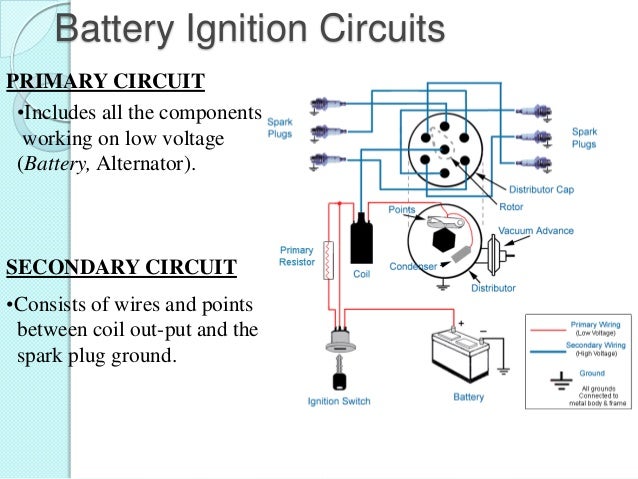

Most of the

modern spark-ignition engines use battery

ignition system. The essential components of battery ignition system

are a battery, ignition switch, ballast resistor, ignition coil, breaker

points, condenser, capacitor distributor and spark plugs.

The breaker

points, condenser, distributor rotor and the spark advance mechanisms are

usually housed in the ignition distribution. The breaker points are

actuated by a shaft driven at half engine speed for a four stroke cycle

engine. The distributor rotor is directly connected to the same shaft.

The system has a

primary circuit of low-voltage current and a secondary circuit for the

high-voltage circuit.

The primary

circuit consists of the battery, ammeter, ignition switch, primary coil winding

and breaker points. The primary coil winding usually has approximately 240

turns of relatively heavy copper wire wound around the soft iron core of

ignition coil.

The secondary

circuit contains the secondary coil windings, distributor, spark plug leads and

the spark plug. The secondary windings consists of about 21000 turns of

small, well insulate copper wire.

Schematic

diagram of Battery Ignition System

When the

ignition switch and the breaker points are closed a low-voltage current flows

from the battery through the primary circuit and builts up a magnetic field

around the soft iron core of the ignition coil.

When the breaker

points are opened by the action of the cam on the distributor shaft, the

primary circuit is broken and the magnetic field begins to collapse, an induced

current from the collapsing magnetic field flows in the same direction in the

primary circuit as the battery current and charges the condenser which acts as

a reservoir for the flowing current due to a rapidly collapsing magnetic field,

high voltage is induced in the primary (it might be as high as 250 volts) and

even higher in the secondary (10,000 to 20,000 volts).

The high voltage

in the secondary passes through the distributor rotor to one of the spark plug

leads and into the spark plug. As soon as sufficient voltage is built up

in the secondary to overcome the resistance of a spark plug, the spark arcs

across the gap and the ignition of the combustible charge in the cylinder takes

place.

The induced

current in the primary to overcome the resistance of a spark across the gap and

the ignition of the combustible charge in the cylinder takes place. The

induced current is the primary, as it was pointed out above flows in the same

direction as it did before the breaker points opened up and charges the

condenser.

The increasing

potential of the condenser retards and finally stops the flow of current in the

primary circuit and the rapidly ‘backfires’ or discharges again through the

primary, but in the direction opposite to the original flow of

current. This rapid discharge of condense produces directional oscillation

in the current flow in the primary circuit.

This oscillation

is weekend with every succeeding reversal in the current flow until the

original potentials and the direction of current flow the primary circuit are

established. The discharge of condenser by itself does not produce the spark,

but only hastens the collapse of the magnetic field around the soft iron core.

The condenser,

which has a capacitance range from 0.15 to 0.24 mf in the automotive system,

not only assists in the collapse f the magnetic field, but also prevents arcing

at the breaker points by providing a place for the induced current to flow in

the primary circuit.

If the condenser

is too small or too large, the breaker points will lead to excessive pitting

will result the breaker points and the distributor must be carefully

synchronized with the crankshaft of the engine to give the proper timing of the

spark in each of the cylinders. The breaker is often refereed to as the

timer, since the time or point in the cycle that the spark occurs depends upon

the time of opening of the breaker points.

The spark plug

leads are called the ignition harness. Since the lead carry a very high

potential, a special insulation is required to prevent a short circuit. Even

with the special insulation, these leads are subjected to breakdowns which

result in high-tension short circuits and to leakage that lower the voltage

available at the work plug. Also, the leads should be shielded to aid in the

prevention of radio interference.

Comments